How to Become a Tool and Die Maker?

Master the art of creating precision tools and dies! Learn the skills, eligibility, and career opportunities for Tool and Die Makers.

In this Career Outline

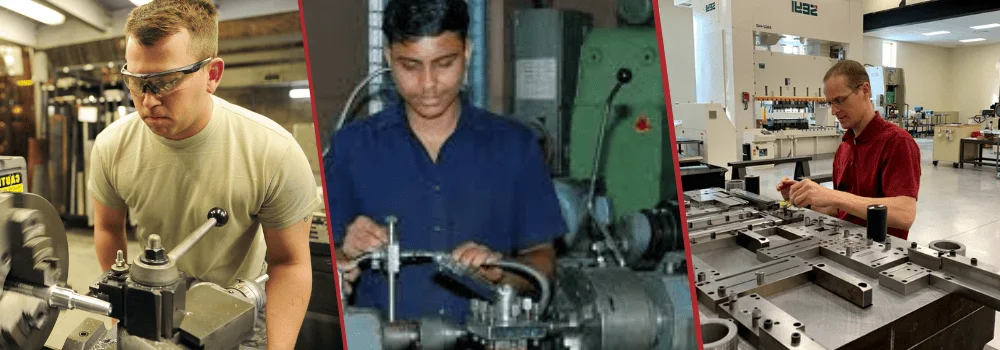

Introduction to Tool and Die Maker

“A Tool and Die Maker doesn’t just shape metal; they shape the future of manufacturing.”

Ever wondered who crafts the tiny yet powerful tools that shape industries? Tool and Die Makers are the backbone of manufacturing, creating precision tools, molds, and dies used in various industries—from automobile and aerospace to medical equipment. With the global manufacturing industry valued at over $15 trillion, the demand for skilled Tool and Die Makers is ever-growing. If you love working with your hands, have an eye for detail, and enjoy problem-solving, this could be the perfect career for you!

Steps to Become a Tool and Die Maker:

Step-1

A strong foundation in mathematics, physics, and engineering drawing will help.

Step-2

Enroll in a Diploma in Tool and Die Making or a related ITI (Industrial Training Institute) course.

Step-3

Hands-on training under experienced professionals is crucial.

Step-4

A Bachelor’s degree in Mechanical Engineering or a related field can offer better career prospects.

Step-5

Work in tool rooms, die-making workshops, or manufacturing units to refine your expertise.

Step-6

Learn about CAD/CAM software, CNC programming, and automation to stay ahead in the field.

Eligibility Criteria

| Eligibility Criteria | Description |

|---|---|

| Eligibility | Must possess at least 50% aggregate from a recognized institution (PUC/CBSE/ICSE/ISC, etc.) |

| Educational Background | 10th or 12th pass with a strong foundation in Mathematics and Science. |

| Undergraduate Degree | Diploma, ITI certification, or a Bachelor's in Mechanical/Manufacturing Engineering. |

| Postgraduate Degree | M.Tech in Tool Engineering, if you aim for research or senior positions. |

| Entrance Exams | Varies by college; some require state or national-level engineering entrance exams like JEE or state polytechnic exams. |

- Must have at least 50% aggregate marks from a recognized board (PUC, CBSE, ICSE, ISC, etc.).

- A 10th or 12th pass with a strong foundation in Mathematics and Science is essential.

- Pursue a Diploma, ITI certification, or a Bachelor's in Mechanical/Manufacturing Engineering.

- An M.Tech in Tool Engineering is recommended for research or senior-level positions.

- Some colleges require JEE Main, state polytechnic exams, or other engineering entrance exams after 12th.

Not eligible to pursue this career?

Find out different career options based on your current academic accomplishments. Enquire with our career experts and build a roadmap to your career success!

Tasks to perform as a Tool and Die Maker:

Knowledge & Skills Required

A Tool and Die Maker must possess a wide array of skills to succeed in their careers. Here are the key knowledge areas and skills needed to excel in this field:

| Knowledge Required | |

|---|---|

| Understanding how sound behaves in different environments | Selecting appropriate materials for tools and dies |

| Designing and simulating precision tools | Programming and operating CNC machines |

| Ensuring accuracy and durability of products | Maintaining a safe working environment |

| Skills Required | |

|---|---|

| Attention to Detail | Analytical Thinking |

| Manual Dexterity | Computer Literacy |

| Problem-Solving | Communication Skills |

Understanding what are soft skills? and why is it important, as they complement technical abilities and enhance overall performance in the field of a Tool and Die Maker.

The Knowlegde and Skills don't intrigue you?

Your career may not align with your interests. Identify them and match with careers requiring those skills for faster growth and success!

Job Roles Offered for a Tool and Die Maker:

Once you qualify as a Tool and Die Maker, you have diverse career options after 12th which course is best for future:

Designs precision tools, dies, and molds using CAD software to create detailed blueprints. Works closely with engineers and production teams to refine designs for efficiency and durability. Ensures tools meet industry standards and client specifications.

Writes and optimizes CNC machine programs to manufacture precision components. Translates CAD blueprints into machine instructions, ensuring high accuracy and smooth operations. Regularly tests and fine-tunes programs to improve production efficiency.

Specializes in creating and repairing molds used in plastic, metal, and glass industries. Uses CNC machines, lathes, and hand tools to shape and maintain molds. Ensures molds are of high quality to support mass production with minimal defects.

Ensures tools, dies, and molds meet strict industry standards by conducting quality checks. Uses precision measuring instruments to inspect components and identify defects. Works with production teams to improve product quality and reduce errors.

Manages tool-making processes in large manufacturing units, ensuring efficiency and cost control. Oversees workflows, machine utilization, and troubleshooting to maintain smooth operations. Collaborates with designers and technicians to enhance production quality.

Repairs and maintains tools, dies, and manufacturing equipment to prevent downtime. Conducts routine inspections, diagnoses mechanical issues, and performs preventive maintenance. Ensures tools remain in optimal working condition for efficient production.

Not sure where you fit in?

With countless career options, choosing the right path can be tough. Analysis and guidance sessions help clarify what to study, pursue, and achieve.

Career Opportunities for a Tool and Die Maker:

Tool and Die Maker can opt for various fields of work in the companies listed below:

| AarKel Tool and Die India Private Limited | Mahindra Group | Tata Group |

| Maruti Suzuki India Ltd | Sansu Automotives Pvt Ltd | Viraj Manpower Services |

| Morya Engineering Pvt Ltd | Jain Tools and Dies Pvt Ltd | Piano Presitel Pvt Ltd |

Colleges Offering Courses in Tool and Die Maker:

If you’re aspiring to become a Tool and Die Maker, here is the list of colleges offering the best courses after 12th:

| Government Tool Room & Training Centre (GTTC), Karnataka | Central Institute of Tool Design (CITD), Hyderabad |

| Institute for Design of Electrical Measuring Instruments (IDEMI), Mumbai | Nettur Technical Training Foundation (NTTF), Bengaluru |

| Indo-German Tool Room (IGTR), Aurangabad | Indian Institute of Tool Design (IITD), Chennai |

End Note

Becoming a Tool and Die Maker is a rewarding career for those passionate about precision engineering and manufacturing. With hands-on training, the right education, and experience, you can excel in this field and contribute to industries worldwide.

Need career counselling? SetMyCareer is here to help! Connect with our experts and take the first step toward a successful future in Tool and Die Making.

In this Career Outline

You don't fit in as a Tool and Die Maker?

Find out your best suitable career by booking an appointment with our experts

Book nowGet In Touch

No. 14/595, 1st Floor, Nanjappa Reddy Layout, Koramangala 8th Block, Bangalore 560095